ABOUT US

Eastport Trading Company was founded in 1982 by Jan Tomczycki, past Sendzimir Sales Manager and former President of Farrell Corp., Andrew Beck, former VP Engineering, Sendzimir Corp., G. William Miller, former Secretary of the US Treasury and past Chairman of the U S Federal Reserve, and past President of Textron Corporation. Eastport was involved in everything steelmaking, rolls, spare parts, backing assemblies, paper interleaf, winders and take up mechanisms, and mill building, buying and selling and moving of rolling mills and the building and rebuilding of Z-Mills.

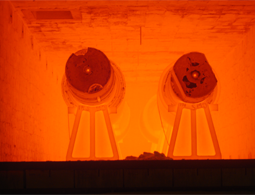

Michael Schermerhorn, a long time Carpenter Steel employee and entrepreneur, joined Eastport in 1999. Michael was an expert in roll production and heat treatment having owned and managed Foster Associates, a forged roll maker and Z-Mill parts producer in Holden, MA, and salt bath heat treater in Waterbury, Connecticut. He partnered with Sorbit d.o.o. and shifted production of Eastport rolls to Ravne na Koroskem, Slovenia –home of 400 years of Metal Production and world renowned tool steel maker Metal Ravne (Link). The shop grew quickly, and soon tripled in size becoming one of the leading supplier of cluster mill/ z-mill rolls in the world. Michael purchased Eastport Trading Company in 2004 and moved the company first to Medway, MA, then Sherborn, MA where it focused on forged mill rolls.

In 2021, the business activities of Eastport Trading Company were acquired by Rodney Scagline and integrated in Eastport Mill Solutions. Rodney Scagline is a metallurgical engineer with more than 30 years in the metals industry. This includes more than 15 years with the manufacturing of forged and cast rolls with Akers and Union Electric Steel where he became President. Eastport Mill Solutions has relationships with US, European and Japanese manufacturers and is solidly positioned to provide “Roll Solutions to Improve Mill Performance” into the future.